How to optimize the safety stock?

29 November 2022

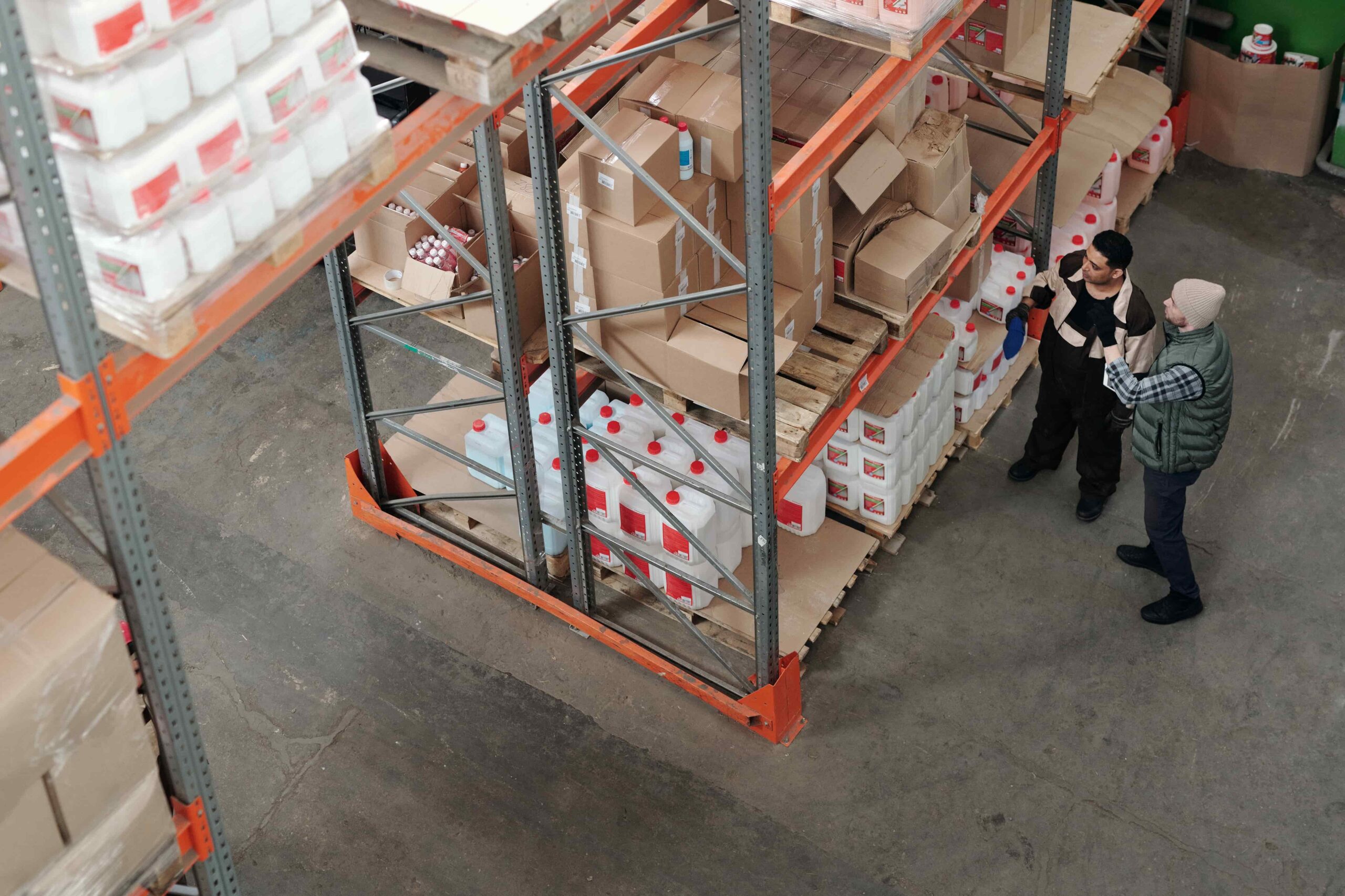

Safety stock is an important part of the business, but it also requires costs. A good alert system is necessary to minimize stock loss and avoid losses when inventory is below the optimal level. Efficiency allows us to evaluate cost reduction opportunities and optimize our safety investment by maximizing ROI.

Safety stock is important, but it also requires costs

Safety stock is important, but it also requires costs. Generally, safety stock is defined as the level of materials and products that are needed to meet a given demand in a specific period. The cost of safety stock can be a significant source of expense for companies; however, there are ways to minimize it.

While there are several ways to optimize safety stock (e.g., by selling or rejecting orders), there are the following tools: market behavior budgeting and planning; estimated budgeting based on historical data; computer systems for statistical inventory management (SIGEI)-programs slightly adapted for use in small businesses. All of these help to minimize the costs associated with stock and improve its utilization within the organization.

Stock levels can be difficult to adjust

In order to adjust the level of stock, you need to know three things:

- Your demand (the number of units you sell per period)

- The lead time (how long it takes to get a new unit from your supplier)

- The safety stock (the number of extra units you need in case some fail or are damaged)

The first two factors are easy to determine as they are fixed and known. The third factor depends on the service level that is desired by your customer-if they want fast delivery, then you should have more safety stock and less inventory. If they are happy with longer delivery times, then having less safety stock means lower costs for holding inventory.

A good alerting system is necessary

A good alerting system is the key to your inventory management system. It’s all about visibility, so you need to be able to be able to see what’s going on with each item and its location in real time (or as close as possible).

Alerts are important because they let you know when something goes wrong. They can be actionable or passive depending on the situation, but what matters most is that they’re timely and informative. If an alert doesn’t trigger until after a problem has occurred, then it won’t actually help much in preventing future issues from occurring!

That’s why it’s important for alerts to include visual representations of data or other helpful information like instructions on how best to go about resolving the issue at hand before addressing other problems with similar root causes later down the road.

Productivity and quality

Companies that have achieved a high degree of operational and productive efficiency have the ability to analyze and understand the real impact that each investment has on their results. Therefore, they are able to identify where there is room for inventory optimization and establish the necessary corrective policies.

Maximize ROI

To maximize ROI, it is necessary to optimize inventory through the use of appropriate software. The use of inventory management software is a crucial element for the proper management of stock and all that goes with it (computers, space, personnel). It is also closely related to other areas such as warehousing and transportation costs.

But what does it mean to optimize? That’s where the problems lie: in many cases things have not been done properly and the result is expired products or products in poor condition or overstocked or missing products. The key to achieving this is two tools: a proper IT system and a continuous improvement plan based on real figures.

1The impact of Customs on Logis...

1The impact of Customs on Logis...28 May 2024

2Choosing a Reliable Transport ...

2Choosing a Reliable Transport ...08 April 2024

3Data in Logistics: Revolutioni...

3Data in Logistics: Revolutioni...13 February 2024

specific topic?

Comments (0)

There are no comments yet. Be the first!